Lander Power Source

The lander must have a reliable source of power to be able to safely transport at least one astronaut to and from the moon.

The power source must provide the energy needed for life support systems, navigation systems, and communication systems.

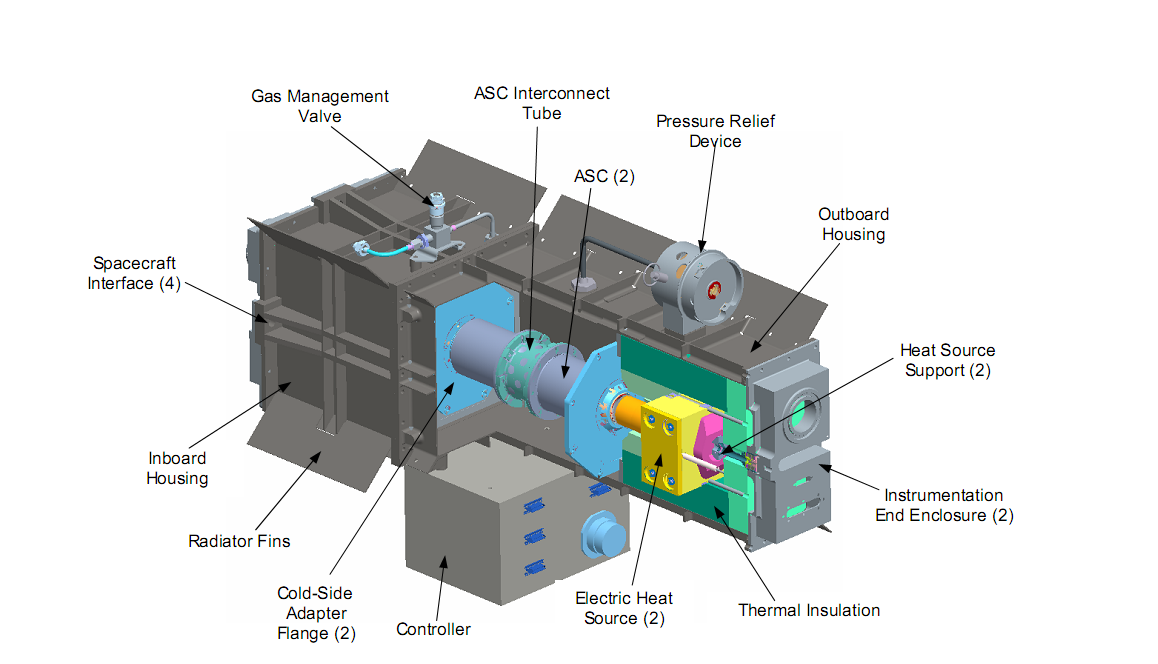

We propose the use of a Radioisotope Thermoelectric Generator, RTG. We will be using the Advanced Stirling Radioisotope Generator,

ASRG, designed for the Titan Mare Explorer. The design is a joint effort by the US Department of Energy and NASA and will be in experimental

use on the Titan, scheduled to launch 2015.

There are a few key benefits of using this RTG design. The first and most important advantage is the efficiency at which this design converts

thermal energy to electric energy. The design utilizes the Stirling cycle to achieve high conversion efficiencies near 40%. In previous designs,

thermocouples have been used to harness the thermal emission of decaying Plutonium 238 isotope with an efficiency of 3-7%. Nominal output power

from the ASRG system is 140 W DC at launch with 0.8% degradation per year. The lifespan of the ASRG is 14 plus years. The ASRG will also require

a fraction of the Plutonium 238 used in previous missions. The ASRG will require .8 kg of Plutonium 238 compared to the 7.8 kg used for the Cassini

mission (a 4th of the fuel source Plutonium 238 will be required). This will provide a safer payload and will require a very thin lead shield for radiation

containment.

Engineering CAD drawing of the ASRG

Of the 140 W, only 10-20% will be used for our communication link to the astronaut walking on the surface of the moon. Since this usage will be for short periods of time, we do not anticipate any power issues. For longer moon walks, a power budget may be created to provide the astronaut reliable power for his mission. This means turning off the refrigerator, the HVAC, the onboard navigation system, etc...

CommPak Power Source

The power source will be custom designed by the SAFT battery group and will be a battery pack similar to SAFT's SALLY series of power packs.

The pack consists of 3 MP 174865 lithium-ion cells producing 11.25 VDC and a nominal energy of 59.62 Wh. The capacity of each pack is 5.3 Ah at 1.2 A load.

If we can minimize our system for a load current of 2 A, we would get approximately 2 hours run time for each pack. The packs would provide approximately

30 W of power over a period of 2 hours. The discharge cutoff voltage for the SALLY series batteries is set at 8.1 V. We will have to relax this constraint

since most of the RF equipment is designed for operations at 5 V. Relaxing this constraint will allow for a longer battery run time and may exceed

expectations.

A power controller/regulator will be used to regulate the voltage at 5 V and will be used to switch between packs to provide uninterrupted power.

Four packs will be used for power giving us a total of 8 hours run time. The dimension of each pack is 145 mm x 62.6 mm x 55.5 mm with a weight of 530 g.

Adding more battery packs would not come at a significant cost if a longer mission is desired. The controller will signal the astronaut at 70% power,

indicating that he must start walking back to the lander.

The battery packs will be housed in a semi-rigid enclosure allowing integration with the body suit, the layer of clothing directly under the heavy

space suit. In previous missions, a cool-liquid garment is used to regulate an astronautís body temperature within an acceptable range. On this mission,

the astronaut will be wearing a body suit provided by Outlast Technologies, a pioneer in PCM (phase change materials). The PCM body suit will actively

regulate the astronautís body temperature via solid-solid phase changes. The technology uses thermocules, materials that absorb or discharge energy

as it changes states from solid to liquid or from solid to solid. The battery packs and power controller will be enclosed in the same PCM casing and

be attached to the astronaut's body suit. This will effectively keep the batteries near body temperature and the heat produced from the batteries will be removed

from direct skin contact. The batteries will work at a regulated temperature increasing the efficiency of the packs.

The controller will consist of four DS2762 Li-ion battery health monitor chips that consistently check the online battery for a depletion state, Vin < Vuv,

for more than a set time (bias adjustable). Once the pack is detected as being depleted, the DS2762 chip will go into sleep mode. The PIC microcontroller sees

the DQ line go low and turns on the next DS2762 and starts using the next battery pack.